Our Team is available from 8:30am-5pm Mon-Fri | 805-375-7676 | customerservice@cad-cam.com

ROBOZE 3D PRINTING SOLUTIONS

ROBOZE 3D Printing Solutions delivers the most accurate 3D printing technology for producing parts with super polymers and composite materials to replace metals in industries with extreme working conditions. As an official ROBOZE reseller, CCCS provides sales, installation, service, and support for equipment, materials, and software to multiple industries throughout Arizona, California, Hawaii, and Nevada.

WHAT IS ROBOZE?

ROBOZE produces the most accurate additive manufacturing technology in the world for high performance super polymers and composites, replacing the use for metals in its process. These 3D printing solutions address industries such as aerospace, automotive, defense, education, energy, medical, motorsport, R&D, transportation, and more in the manufacturing industry.

With solutions for Professional and Production use, ROBOZE utilizes three tiers of materials (super polymers and composites, techno polymers, and standard polymers) ensuring optimal performance across various industrial applications by categorizing these materials based on their thermal resistance, mechanical properties, and chemical resistance. This approach enables customization and flexibility, providing them with the tools to create durable and high-precision parts tailored to their specific requirements. Moreover, ROBOZE's focus on sustainability is evident in their commitment to developing eco-friendly materials and recycling programs, aiming to reduce the environmental impact of 3D printing technologies.

Professional Use – ROBOZE Plus PRO

The ROBOZE Plus PRO is an advanced 3D printer designed for professional use, featuring high precision and the ability to work with a wide range of materials, including high-performance polymers. Two key value points of the ROBOZE Plus PRO are:

- Precision & Versatility: The ROBOZE Plus PRO excels in printing complex, highly accurate parts, ideal for supporting industrial manufacturing processes. It is compatible with various high-grade materials, enhancing part durability and performance.

- Cost-Efficiency & Adaptability: This 3D printer minimizes waste and inventory costs with on-demand production capabilities. It boosts operational adaptability, reducing production times and costs, and allows quicker responses to market demands.

Production Series – ROBOZE ARGO 500 and ARGO 1000 HYPERMELT

The ROBOZE ARGO 500 and ARGO 1000 HYPERMELT are state-of-the-art 3D printers designed for industrial use. The ARGO 500 offers high precision and complex part production, while the ARGO 1000 HYPERMELT features larger scale printing and enhanced part durability with its HYPERMELT technology. Both excel in handling high-performance materials, providing robust solutions for demanding industrial applications.

Precision and Efficiency in Industrial 3D Printing: The ARGO 500 combines industrial-grade capabilities with high throughput, designed to manufacture complex and precise parts for industrial applications, while its material versatility and efficiency support diverse part properties with minimal waste, optimizing operational costs and production efficiency.

Large-Scale Efficiency & Innovation: The ARGO 1000 HYPERMELT is designed for large-scale production with its capability to print massive, durable parts, making it perfect for sectors like automotive and aerospace. Its innovative HYPERMELT technology not only enhances part density and strength but also expands application possibilities, while providing cost savings by optimizing production processes and diminishing reliance on traditional manufacturing.

Materials

- Super Polymers can sustain a continuous use temperature up to 300 ◦C. These materials include CARBON PEEK, PEEK, PEKK, TOOLING X CF, and ULTEM™ AM9085F.

- Techno Polymers can sustain a continuous use temperature up to 150 ◦C. These materials include BIO-BASED PA, CARBON PA PRO, and FUNCTIONAL-NYLON.

- Standard Polymers can sustain a continuous use temperature up to 100 ◦C. These materials include ABS-STRONG, FLEX-TPU, PP PRO, and ULTRA-PLA.

WHY USE ROBOZE?

ROBOZE helps innovators throughout the world transform their ideas into components and projects that affect our daily lives wherever extraordinary performance is required. Manufacturing companies around the world can create a more efficient production process to develop cutting-edge products. With their one-of-a-kind technology, we are at the forefront of a new industrial revolution – one that is sustainable and future oriented – together.

- The patented beltless system boasts mechanical repeatability, superior tolerances, and low maintenance.

- The patented HVP extruder optimizes the flow of high viscosity polymers, reduces shrink rate, and avoids clogging that the competition struggles to achieve.

- The insulated heated chamber can reach extreme temperatures with uniform airflow and controlled temperature, and doesn’t require thermal post processing, which saves you a step.

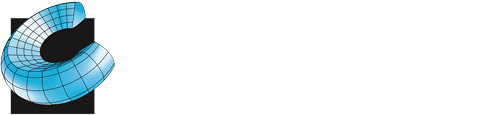

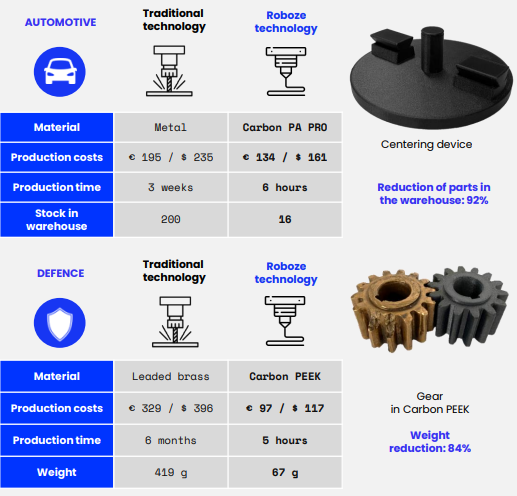

- ROBOZE technology vs traditional technologies have seen dramatically reduced production costs and time, with real-world applications seeing weight reductions of 84%, and cost savings of over 70%.

- Partnering with CCCS for your manufacturing needs gives you the benefit of a single source of knowledge that is available via any form of communication to trouble shoot issues, train your staff, and get you out of a bind.

Industrial Production Challenges

HOW TO GET ROBOZE

ROBOZE products and materials are available for sale through CCCS in Arizona, California, Hawaii, and Nevada. Items are stocked and ready to ship upon purchase and are housed in the Houston, TX ROBOZE HQ, which provides a shorter lead time for the machine to hit your floor. Our team will come on-site to install your equipment and get you up and running.

If you are interested in printing a part before purchasing a machine, CCCS offers that service as well.

CONTACT US

Contact Us

We will get back to you as soon as possible.

Please try again later.