Additive Manufacturing Digital Newsletter – Q4 2023

Welcome to the Q4 2023 edition of the CCCS Additive Manufacturing Digital Newsletter!

Take Part In Our AM Survey

We’re interested to see what our audience knows about AM. In this short survey, let us know what technologies you’re familiar with, if you’re currently using or are in the process of evaluating AM, or even why you haven’t decided to employ this tech in your shop.

If you take part in the survey before December 22, you’ll be entered to win a $100 Amazon gift card. Take the survey HERE.

Free Additive Webinar March 14, 2024

Join Axel Fernandes, our Additive Manufacturing Lead, along with representatives from companies in the AM sector as they offer their practical insights and best practices for the software that supports 3D printing/AM. Everything from how the software currently can be used to solve problems to what’s on the horizon for software that supports AM will be covered. The aim of this webinar is to inspire the multidisciplinary engineering audience with advancements AM.

This webinar is produced by Machine Design, and will be broadcast on March 14, 2024. Stay tuned for a registration link!

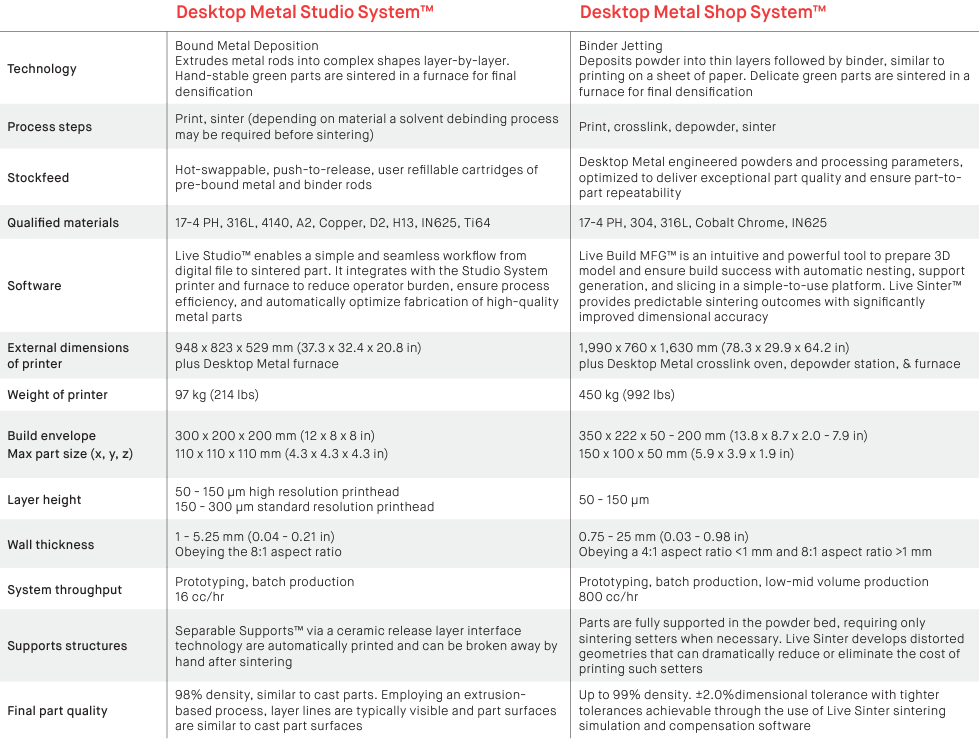

Desktop Metal: Studio System vs. Shop System

Metal 3D printing is poised to launch the next revolution in manufacturing, with benefits that stretch from the factory floor to international supply chains. Desktop Metal is leading the way with two print-and-sinter metal 3D printing technologies that prioritize ease-of-adoption and pair with the Desktop Metal Furnace for a production-ready process. Here’s an overview of the Studio and Shop Systems, which are plug-and-play options to get you started with metal 3D printing.

Mastercam APlus Add-On

Mastercam partner CAMufacturing has developed APlus, an Add-On to Mastercam developed specifically for AM. Using the same interface Mastercam users are familiar with, APlus customers can program, backplot, and simulate their 3D printing scenarios just like they would with traditional toolpaths in Mastercam.

APlus by CAMufacturing is designed for AM using Direct Energy Deposition (DED) and has toolpaths developed specifically to handle any geometry in AM, as well as features and utilities designed to remove uncertainty out of the process and to improve efficiency. APlus can be used with Mastercam Mill, Lathe, or Router licenses (except for Entry).

To find out more, go to www.mastercam.com/solutions/aplus.

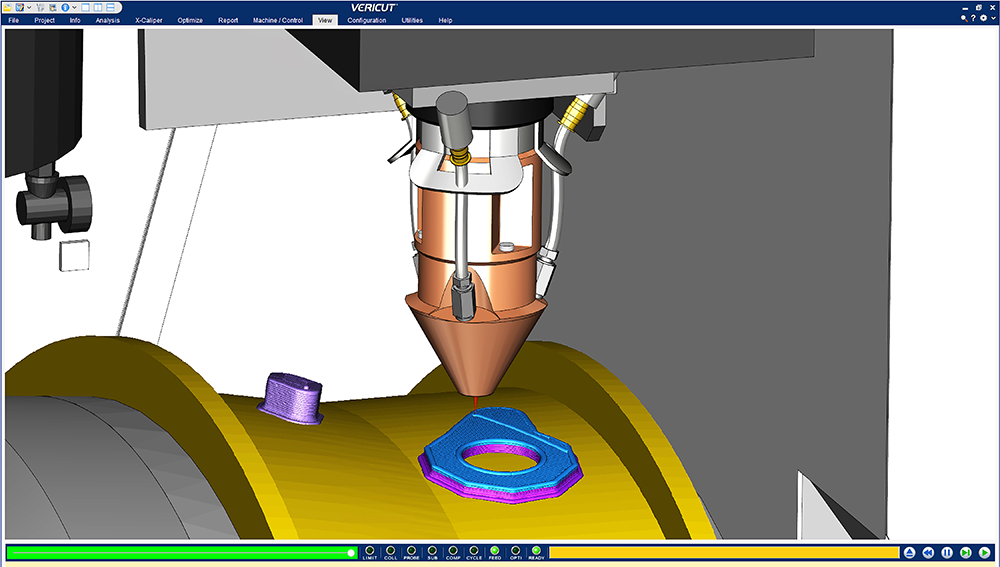

CGTech VERICUT® Additive Module

VERICUT’s Additive module simulates both additive and traditional machining (milling or turning) capabilities of new hybrid CNC machines. It has various features and benefits such as:

- Verifies laser activity. The Additive module provides CNC machine simulation for accurate laser cladding and material deposition. VERICUT reads the laser parameters, controls laser wattage, flow of carrier gas, and metallic powder specific to each job/material type.

- Detect collisions. VERICUT detects collisions between the machine and the additive part with its collision checking extended to cover additive parts as they’re being built, and expensive hybrid machine laser equipment. This provides the ability to gauge potential problems beforehand.

- Quick access history. With droplet technology, VERICUT’s additive model is much more than just “deposited material.” Each bead contains valuable history information about how it got there. This saves time investigating errors, voids, or misplaced material since the source of the problem is revealed with just one click.

- 5-Axis machining. The verification process of VERICUT accurately checks for errors on all 5-axis milling, turning, and additive laser sintering processes no matter how complex the machining operation.

- G-Code – Hybrid machines. Simulation is powered by the same post-processed NC code used to drive the CNC machine, which enables the user to ensure additive functions are within proper ranges. VERICUT makes it simple to alternate from additive, to cutting, and back to additive in any sequence.

- Large Scale Additive Manufacturing (LSAM). The Additive module supports simulation of both Large Scale Additive manufacturing (LSAM) and Big Area Additive Manufacturing (BAAM) machines and processes.

- Realistic appearance. The Additive module offers superior simulation of material deposition that is easily distinguished from cut stock. Therefore, having the ability to clearly see where each bead of material is placed in a step-by-step process is essential for AM.

Find a more in depth look at the VERICUT Additive Module

HERE and check out this short overview video

HERE.

CCCS Holiday Schedule

With the holiday season underway, we wanted to update you on a few days we’ll be closed.

- December 22 (1/2 Day PM)

- December 25

- December 29 (1/2 Day PM)

- January 1

We hope you’ve enjoyed this newsletter specific to Additive Manufacturing! Be sure to follow us on social media for more frequent updates at the links below, and if you have any questions feel free to call or email any time.