CGTech VERICUT® Products

CAD/CAM CONSULTING SERVICES INC. offers Vericut software, which is the industry standard for simulating CNC machining in order to detect errors, potential collision, and areas of inefficiency. Used by companies of all sizes, universities/trade schools, and government agencies in over 55 countries, Vericut enables you to reduce or eliminate the process of manually proving-out NC programs. It reduces scrap loss and rework, and optimizes NC programs in order to save time and produce higher quality surface finish.

what is vericut?

VERICUT simulates all types of CNC machine tools, including those from leading manufacturers such as Mazak, Makino, DMG Mori Seki, Okuma, etc. VERICUT runs standalone but can also be integrated with all leading CAM systems. VERICUT provides:

VERICUT VERIFICATION

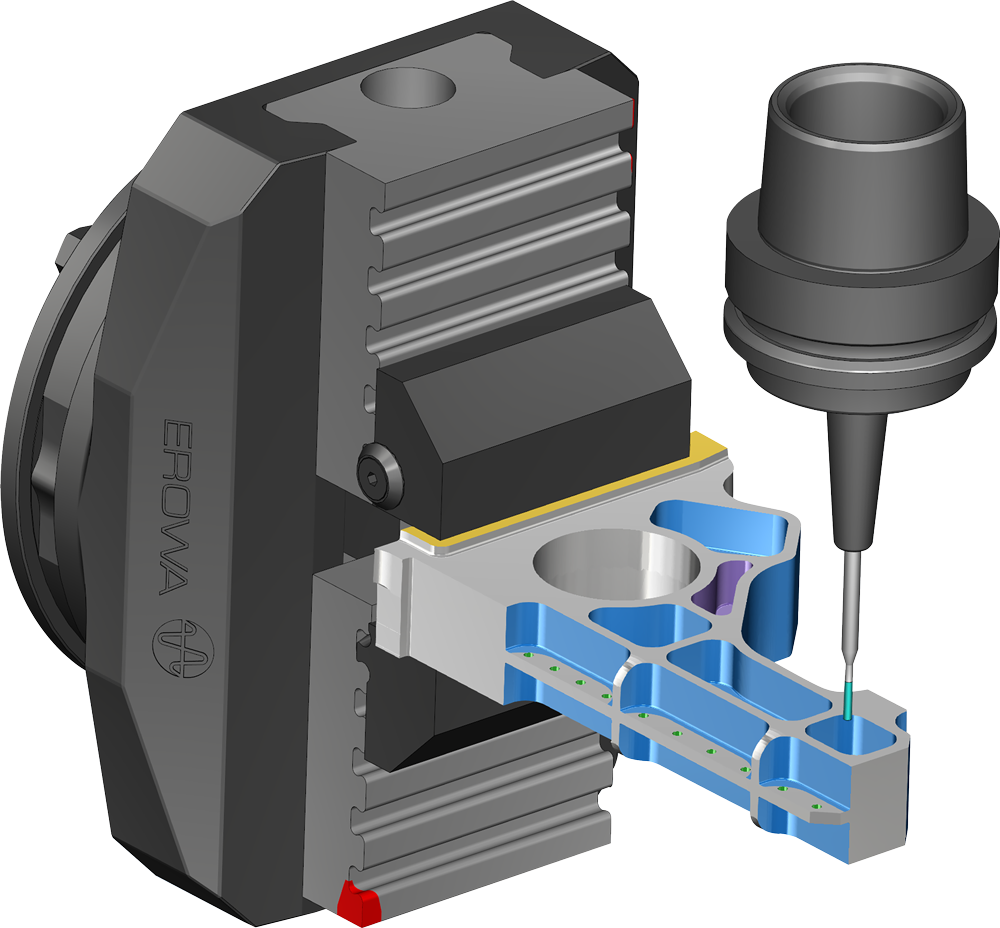

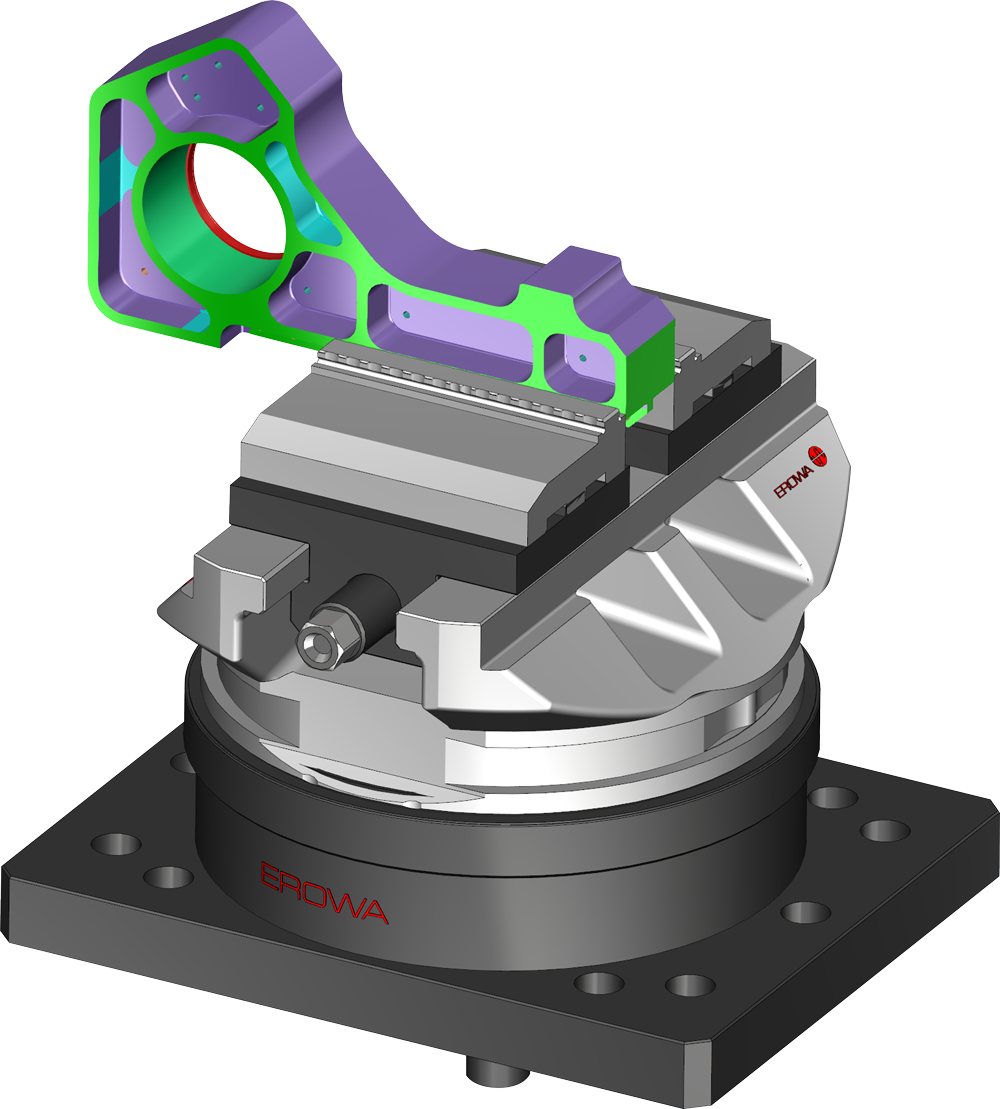

VERICUT is a 3D solids-based software program that interactively simulates the material removal process of an NC program. The program depicts multiaxis milling/drilling as well as multiaxis tuning and combination mill-turn machining. It enables you to verify the accuracy and quality of your NC program. Inefficient motion or programming errors that could potentially ruin a part, damage the fixture, or break the cutting tool can be corrected before the program is run on a CNC machine tool.

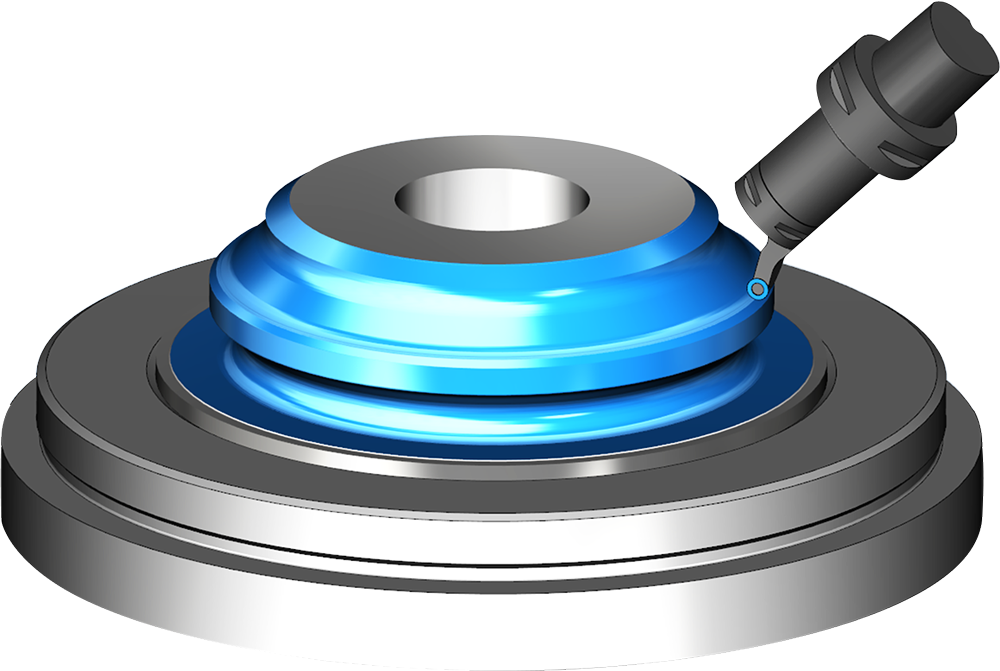

FEED RATE OPTIMIZATION

VERICUT is equipped with NC program optimization capabilities. Based on initial programmed feed rates, VERICUT automatically determines the optimum safe feed rate for each cut. Cycle time can be reduced significantly. Optimized feed rates also result in longer cutting tool life, fewer broken cutting tools and scrapped parts, better quality parts due to minimized cutter deflection, and a better finish on part surfaces and edges due to constant tool pressure.

CNC MACHINE SIMULATION

VERICUT shows material removal at the workpiece level but can also simulate entire machine tools as they appear on a shop floor. Machine Simulation detects collisions and near-misses between all machine tool components such as axis slides, heads, turrets, rotary tables, spindles, tool changers, fixtures, work pieces, cutting tools, and other user-defined objects. A user can set up near-miss zones around the components to check for close calls and detect over-travel errors.

CAD/CAM INTERFACES

CAD/CAM interfaces make verifying and optimizing NC programs, and simulating CNC machines, a much easier and more efficient process. All stock, fixture, and design geometry are automatically transferred to VERICUT in the correct orientation, along with your NC program, tooling, machine, control data, and other simulation parameters. VERICUT interfaces with all the leading CAD/CAM packages, including Mastercam.

Tool management interfaces extract tool lists from your tool manager system and create VERICUT tool assemblies. It is an on-the-fly live connection to your tool manager and supports a wide variety of cutting tool suppliers.

Model interfaces enable VERICUT to read the designated model file formats and use them as stock, fixture, design, tool holder, and machine models. When combined with Model Export, VERICUT’s cut stock may be written out in these formats as well. The modules do not require a CAD/CAM system for VERICUT to read or write any of the formats.

WHY USE VERICUT?

- SAVE TIME: Reduce or eliminate prove-outs and save machine tool, operator, and part programming time – all of which decrease time-to-market.

- INCREASE QUALITY: Verify dimensional accuracy and optimize toolpaths for better finishes on surfaces and edges.

- SAVE MONEY: Reduce or eliminate the cost of machine tool crashes, rework, scrapped parts, and damaged tooling, fixtures, and clamps.

- INCREASE PRODUCTIVITY: Reduce machining times and interrupt production less frequently.

- BUILD CONFIDENCE: Test part programs on a computer so they run right the first time and operators don’t need to keep one hand on the “emergency stop” button.

- CONSERVE RESOURCES: Reduce machine tool wear. Reduce cutting tool wear so cutting tools can be used longer before needing to be reground or replaced.

- IMPROVE SAFETY AND TRAINING: Train programmers, operators, and students without using machine tool time or risking a dangerous, costly collision.

- IMPROVE DOCUMENTATION: Enable operators and managers to preview all machining operations.

HOW TO GET VERICUT

VERICUT is available for purchase or on a subscription basis, depending on which plan is the best for your company. Maintenance is available on an annual renewal for purchased software and is included in the subscription price. Cloud licenses are available and floating seats are allowed to be checked out as needed.

VERICUT provides technical support to currently maintained customers, and also offers implementation and automation consulting, verification audit, optimization mentoring, as well as contract services including machine tool modeling and control building, NC program optimization, and custom tool libraries.