DESKTOP METAL

Desktop Metal® exists to make metal 3D printing and carbon fiber 3D printing accessible to all engineers, designers, and manufacturers.

Desktop Metal

Desktop Metal manufactures 3D printing solutions for all scales of production—from complex prototypes and on-demand tooling to the rapid manufacture of thousands of parts.

Rapid Prototyping

Quickly 3D print functional prototypes and reduce product development timelines.

Mass Production

Produce hundreds of thousands of parts with no tooling required.

Manufacturing Tooling

Simplify the manufacturing process and reduce lead times for end use parts.

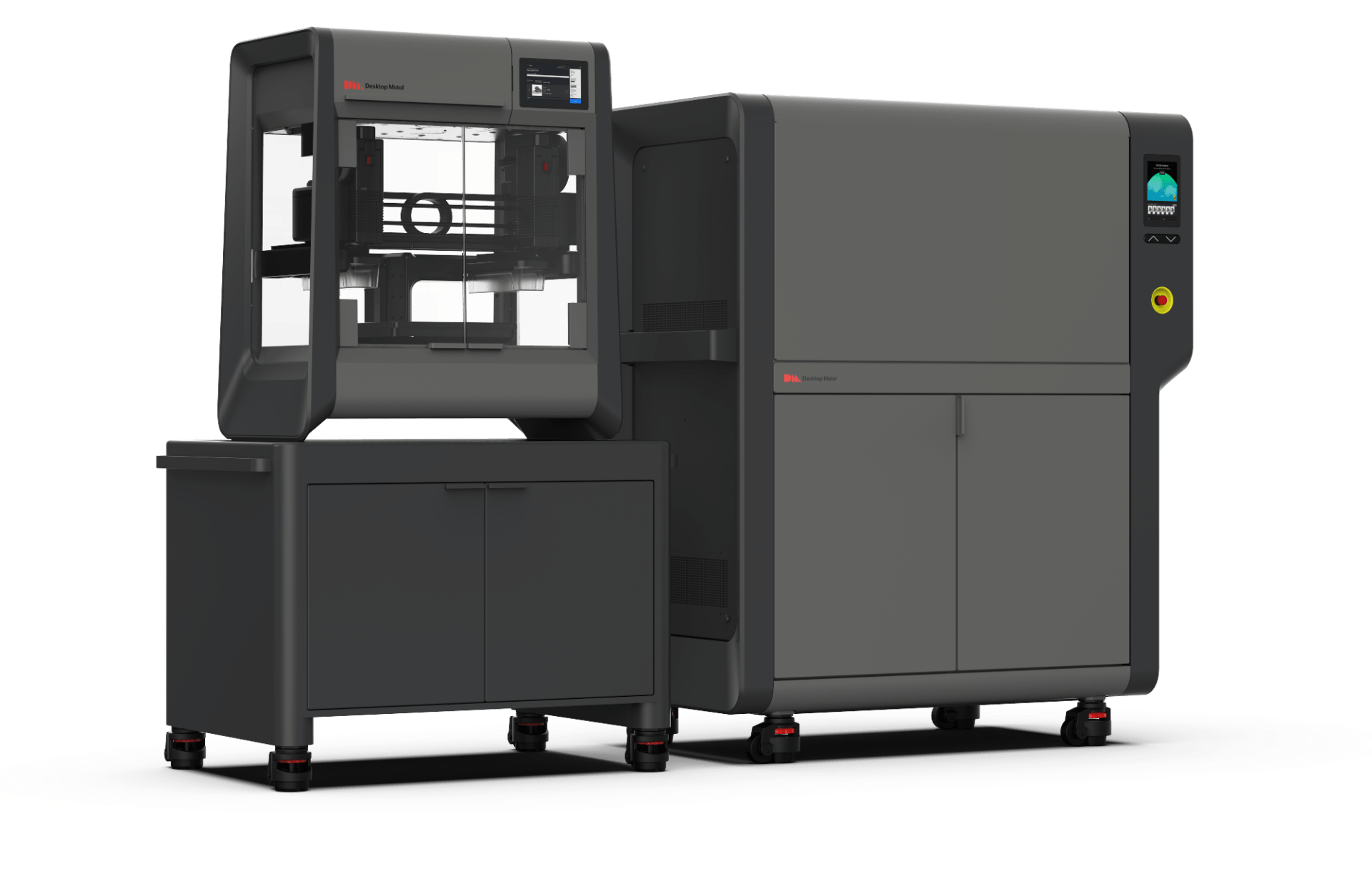

Studio System

The easiest way to print high-quality metal parts in your office.Leveraging an all-new material system, the Studio System™2 eliminates the Debinder (and solvent debind step), unlocking a drastically simpler and more hands-off workflow. Parts no longer need to be batched before debinding, and then batched again before sintering. Now, making metal parts is a simple two-step process that offers improved first-time part success and outstanding surface finish on side walls and support-facing surfaces across a wider range of complex geometries.

- Application

- Prototyping, low volume, Manufacturing tools

- Material compatibility

- 17-4 Stainless Steel, 316 Stainless Steel, H13 Tool Steel, 4140 Chromoly Steel, 625 Alloy, Copper, Titanium-New!

- Technology

- Print with Bound Metal Deposition (BMD), Sinter

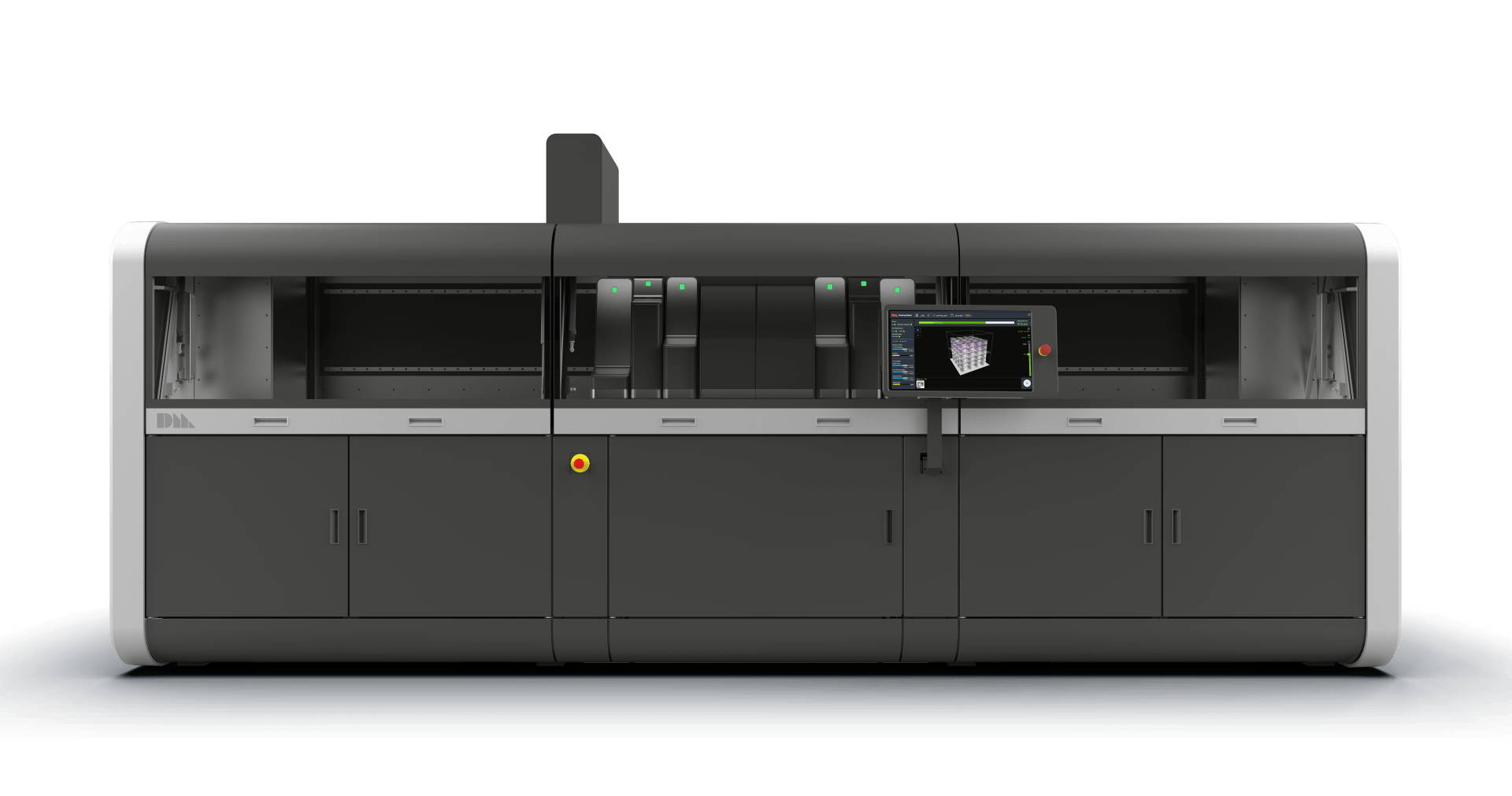

shop system

Introduces high quality binder jetting to an entirely new market of machine shops. Shops can now cost effectively print small end-use metal parts with unparalleled speed and productivity.

- Application

- Mixed volume production, Batch production, mid volume production

- Material compatibility

- 17-4 Stainless Steel, 316 Stainless Steel, Cobalt Chrome

- Technology

- Print with Binder Jetting, Depowder, Sinter

Production P1 and P50

Larger scale production, single pass binder jetting technology in a closed inert environment. Contact us for more information.

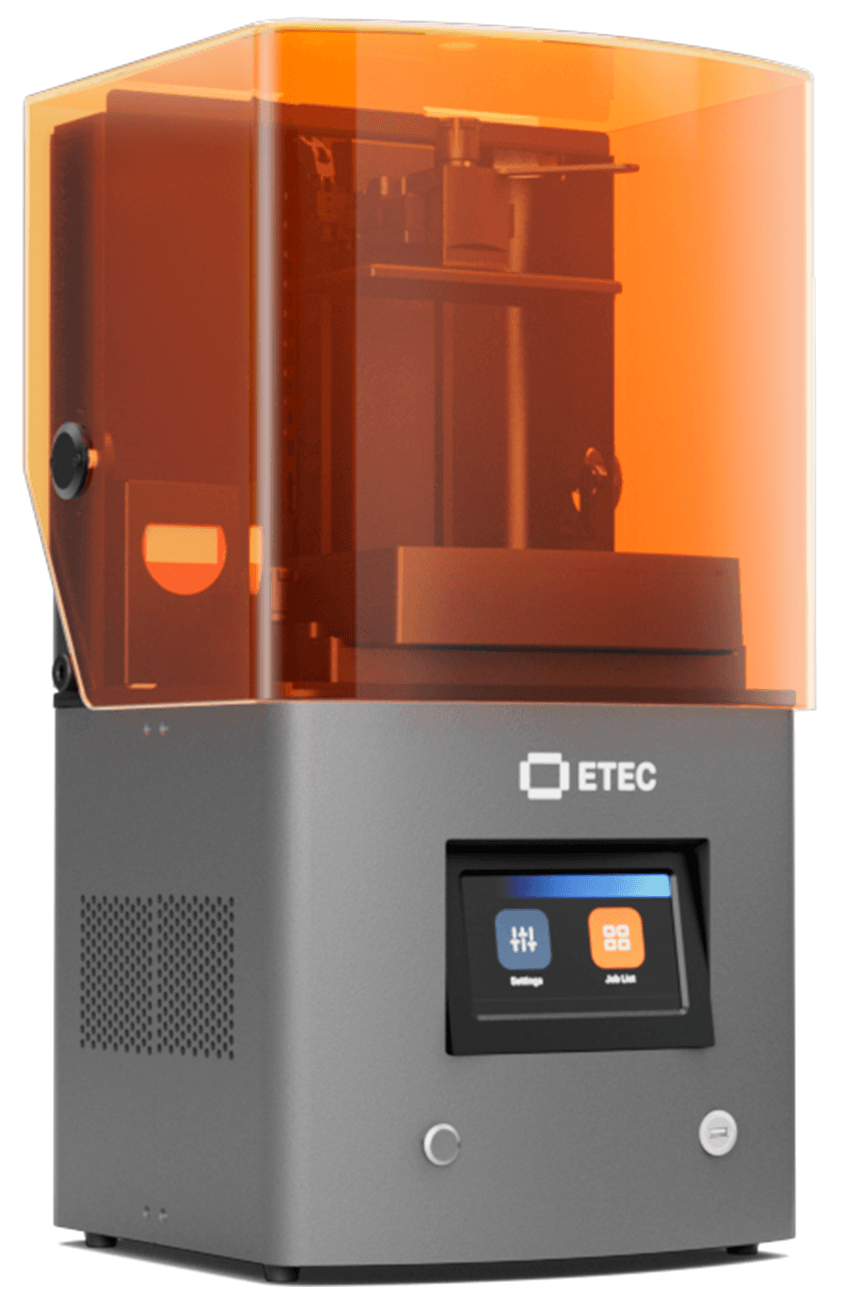

ENVISION ONE

The Envision One features patented CDLM (continuous digital light manufacturing) technology, which enables the ability for continuous printing. With little to no delay between layers, the Envision One delivers exceptional speed, print resolution, surface finish, and part properties.

XTREME 8K

Xtreme 8K offers the largest build area among commercially-available, production-grade DLP printers

The Xtreme 8K makes volume production of 3D-printed parts a reality, with the ability to print thousands of parts per day. With wide material compatibility, including hard plastics, high-temperature plastics, elastomers and rubbers, the Xtreme 8K enables the production of the broadest possible range of parts.

The Xtreme 8K leverages long-chain polymer chemistry to create fully-isotropic, stable, end-use parts, and features a heated vat, allowing users to process highly viscous and solid materials at room temperatures.